1. Tempered Glass

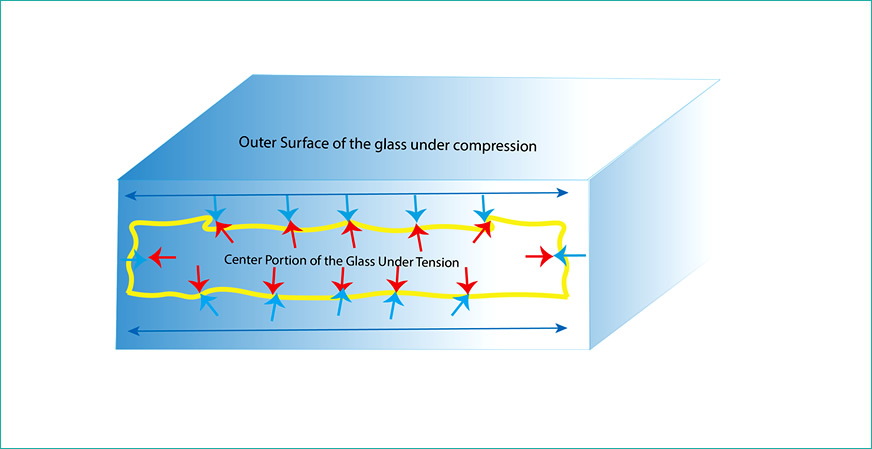

Tempered glass, often referred to as toughened glass, is a type of safety glass with enhanced strength and breakage resistance. This is achieved through a specific manufacturing process involving controlled heating and rapid cooling, creating a state of high surface compression and internal tension. The process begins with cutting the glass to the desired shape, followed by polishing the edges to eliminate sharp edges or burrs. The glass is then heated to a high temperature of about 600°C (1112°F) and rapidly cooled through a controlled air or quenching process. This rapid cooling causes the glass surface to cool and contract more quickly than the interior, creating surface compression and internal tension. The cooled glass is then subjected to controlled cooling to balance the internal tension and surface compression, ensuring its strength and safety properties.

This unique structure imparts tempered glass with notable properties: remarkable strength, increased safety, better heat resistance, enhanced scratch resistance, and a uniform appearance. When tempered glass breaks, it shatters into small, harmless fragments with rounded edges, minimizing the risk of injury compared to regular glass, which breaks into sharp shards. The resulting tempered glass is ideal for applications like automobile windows, shower doors, and architectural uses, where safety and durability are paramount concerns.

2. Double Glazing Glass

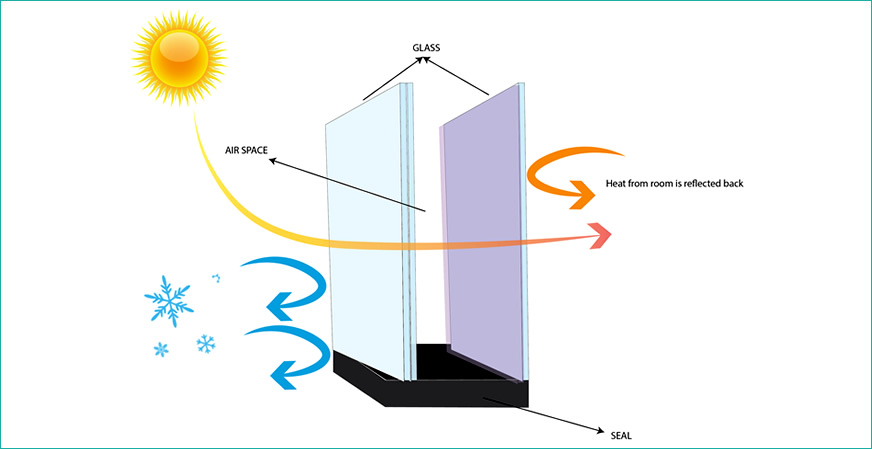

Double glazing glass consists of two glass panes separated by a spacer filled with air or gas. The manufacturing process entails several steps to create this insulating structure.

Firstly, two glass sheets are precisely cut to the desired size and shape. These sheets can have varying thicknesses, depending on the desired level of insulation. Subsequently, a spacer, typically made of materials like aluminum, is positioned along the edges of one glass pane. This spacer establishes a gap between the two glass panes, which will later be filled with air or gas.

Afterward, the two glass panes, along with the spacer, are carefully sealed together to form a tight and well-sealed unit. This sealing process is crucial in preventing moisture from entering the gap between the panes, which helps maintain the insulation's effectiveness. To further prevent condensation and ensure clarity between the panes, a desiccant—a moisture-absorbing material—is often added within the spacer.

In certain cases, the gap between the glass panes is filled with an insulating gas like argon or krypton. These gases are denser than air, thus contributing to improved thermal insulation. Following the gas filling, a secondary sealing step is sometimes employed to ensure the insulating gas remains trapped between the panes

The advantages of double glazing glass are manifold. It provides enhanced energy efficiency by reducing heat transfer, which in turn helps maintain warmer indoor spaces during cold months and cooler environments in the heat. Additionally, the insulation properties of double glazing minimize the likelihood of condensation forming on the inner glass surface during temperature fluctuations.

Double glazing glass finds extensive application in residential and commercial buildings alike, primarily to elevate comfort and energy efficiency. It's prominently used in windows, doors, and glass facades, contributing significantly to improved thermal performance and decreased energy consumption.

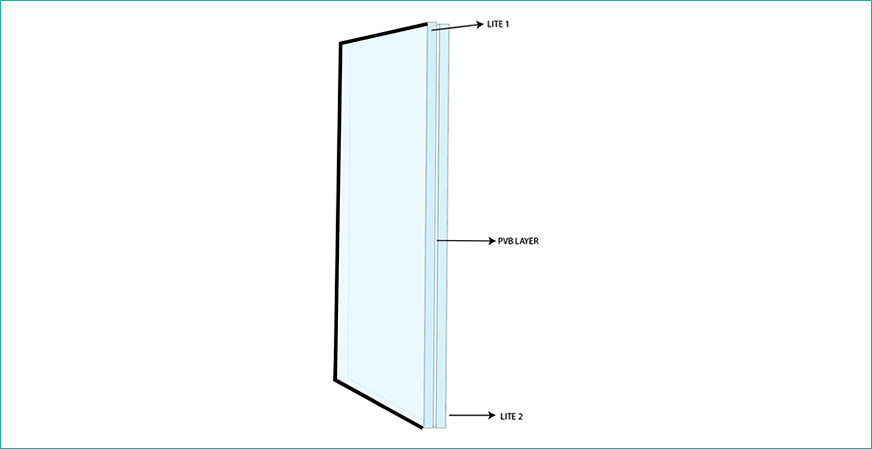

3. Laminated Glass

Laminated glass is a safety glass made by bonding two or more layers of glass with an interlayer material, like PVB or EVA. This interlayer holds the glass together even when broken. The process involves cutting glass to size, preparing the interlayer, stacking the layers together, and subjecting the assembly to heat and pressure in an autoclave. This bonds the layers securely and eliminates defects. Laminated glass offers safety, noise reduction, UV protection, and resistance to forced entry. If shattered, the glass adheres to the interlayer, preventing dangerous shards. The interlayer absorbs sound waves, making it suitable for noise insulation. Applications include windows, facades, skylights, and more, where safety, aesthetics, and comfort are vital.